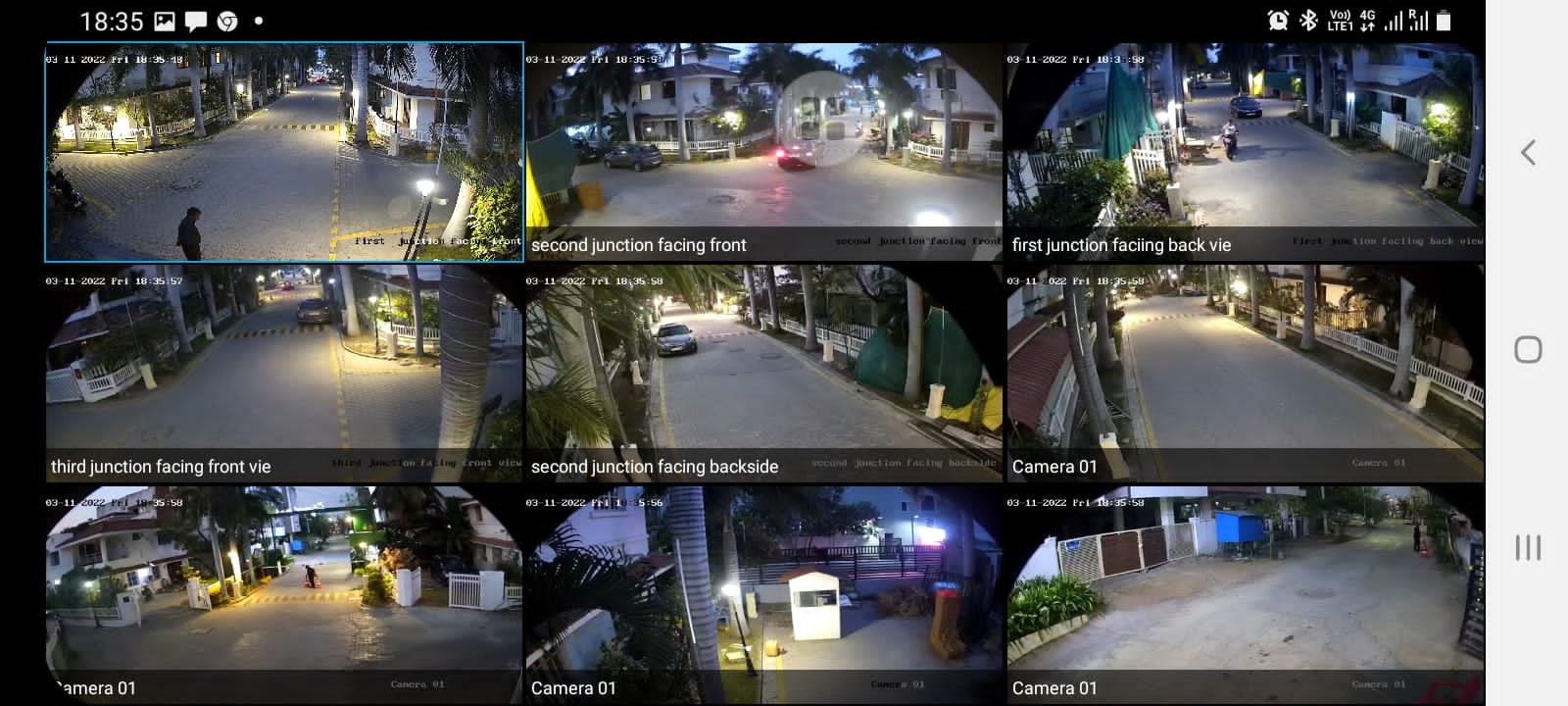

CCTV

Camera

if you’re building a CCTV Camera System, you have two camera options: Internet Protocol (IP) or analog. IP is usually the preferred choice due to its compatibility with most devices. Many different types of cameras can be installed, for example -dome cameras, bullet cameras, covert cameras.Depending on how many angles you want to cover, how many cameras you will need in that specific area, how much resolution or detailing you require when you choose your preferred cameras.Monitoring Station

A monitor arguably facilitates the most important function of a security camera: viewing recorded images and footage. Deciding how many monitors you’ll need is dependent upon what, and which area you are monitoring. You wouldn't need more than three to five screens if you aren't operating in a large-scale facility. Although if your requirements change, you can easily add or remove monitors anytime to match the compatibility of your camera.Cables & Routers

Depending on the type of surveillance system, and cameras you choose, you will need supporting technologies like cables, and routers to be integrated into your system for a seamless connection. For example, wireless systems require a router, while wired versions do not. Therefore, choose the cables, and wires after selecting your cameras, and monitors according to your unique needs.Video Recorders

The video recorder is the device where video recorded on the camera gets processed for storage & viewing. There are two types of video recorders: DVR (Digital Video Recorders) and NVR (Network Video Recorders). You can learn more about them here.Data Storage

Your CCTV security system is only as good as the hard disk backing it. The storage device for a security camera system should be able to record, store and re-play videos non-stop from multiple feeds. Regular hard drives that are used in PCs and Laptops are ill equipped to handle CCTV storage needs. Hence, it is critical to choose a robust storage system for safe data storage.A CCTV Camera System has become a vital necessity in this modern world. While selecting your preferred security system, the 5 essential components you need to give importance to for consistent service are: Camera, Monitor, Cable, Video Recorders, and Data Storage. Now that you know the essential components of a security camera system, you can choose quality products for the safety of yourself and your loved ones.

REVERSE OSMOSIS

On the left is a beaker filled with water, and a tube has been half submerged in the water. As you would expect, the water level in the tube is the same as the water level in the beaker. In the middle figure, the end of the tube has been half-filled with a salty solution and submerged. Initially, the level of the salt solution and the water are equal, but over time, Something unexpected happens - the water in the tube actually rises. The rise is attributed to “osmotic pressure.”

A semi permeable membrane is a membrane that will pass some atoms or molecules but not others, Saran wrap as a membrane, but it is impermeable to almost everything we commonly throw at it. The best common example of a semi permeable membrane would be the lining of your intestines, or a cell wall. Gore-Tex is another common semi permeable membrane. GoreTex is fabric contains an extremely thin plastic film into which billions of small pores have been cut. The pores are big enough to let water vapor through, but small enough to prevent liquid water from passing.

In the figure above, the membrane allows passage of water molecules but not salt molecules. One way to understand osmotic pressure would be to think of the water molecules on both sides of the membrane. They are in constant Brownian motion. One the

Salty side, some of the pores gets plugged with salt atoms, but on the pure water side that does not happen. Therefore, more water passes from the pure-water side to the salty side as there are more pores on the pure-water side for the water molecules to pass through. The water on the salty side rises until one of two things occurs:

The salt concentration becomes the same on both sides of the membrane (which isn’t going to happen in this case since there is pure water on one sides and salty water on the other) The water pressure rises as the height of the column of salty water rises, until it is equal to the osmotic pressure. At that point, osmoses will stop.

Osmosis, by the way, is why drinking salty water (like ocean water)will kill you. When you put salty water in your stomach, osmotic pressure begins drawing water out of your body to try to dilute the salt in your stomach. Eventually, you dehydrate and die.

In reverse osmosis, the idea is to uses the membrane to act like an extremely fine filter to create drinkable water from salty (or otherwise contaminated) water. The salty water is put on one side of the membrane and pressure is applies to stop, and then reverse, the osmotic process. It generally takes a lot of pressure and is fairly slow, but it works.

Reverse osmosis (RO) is used to reduce dissolved solids from feed waters with salinities up to 45,000 ppm TDS (total dissolved solids). Municipalities and industrial facilities are able to use RO permeate as a consistently pure drinking waters supply and to transform drinking water to high purity water for industrial use at microelectronics, food beverage, power, and pharmaceutical facilities. The technology is also very effective at removing bacteria, pyrogens, and organic contaminants.

Reverse osmosis separation technology is used to remove dissolved impurities from water through the uses of a semi-permeable membrane.RO involves the reversal of flow through a membrane from a high salinity, or concentrated, solution to the high purity, or “permeate”, stream on the opposite side of the membrane.

Pressure is used as the driving force for the separation. The applied pressure (P) must be in excess of 5the osmotic pressure of the dissolved contaminants to allow flow across the membrane.

GE Water & Process Technologies uses spiral-bound membranes - tightly packed filter material sandwiched between mesh spacers and wrapped in a small-diameter tube - to desalt and demineralized process water. The membrane's operating conditions are fine-tuned to balance the flux, or the amount of water which passes through the membrane, with the specific rejection rates of contaminants to achieve up to 99.8% salt rejection at low pressures and high flux rates.

A one-stop source for platforms that serve your water purification needs Reverse Osmosis systems from GE deliver high performance at the lowest lifecycle costs. Our pre-engineered systems are built with high-quality components designed specifically for water purification. They arrive at your facility ready to run with all filters, membranes, pumps, piping, controls and automation.

GE spiral-bound membranes are cost-effective thin-film elements used to remove salts and separate organic material, by molecular weight or particle charge. Our products cover a broad range of applications, including: We supply membrane elements, reverse osmosis (RO) systems, filters, pumps, nano filtration and ultra filtration equipment and other components. GE is also unique in our Single Point Accountability for the design and operation of these units. We build the complete machine, but the GE brand is also on the membrane elements, controls, filters and high pressure pumps to insure quality and responsiveness to your concerns.

Iron Removal

(i) aeration/gas transfer, (ii) pH adjustment, (iii) oxidation of ferrous into ferric iron by dissolved oxygen and catalytic action of iron oxide coated contact media, (iv) precipitation of ferric iron, and (v) removal of precipitated iron by sedimentation, up flow and gravity flow filtration.

The unit is designed for 300 l/hr output and can cater to the need of small population particularly, in rural areas. Iron contents in water treated through this unit were found below 0.3 mg/l with feed water having iron contents up to 40 mg/l. The advantages of the unit are

Preamble:

Iron tolerances for municipal or house hold use should not exceed 0.3 ppm. Concentration of Iron in excess of 0.2 to 0.3 mg/l may cause nuisance even though its presence does not affect the hygienic quality of water.

Source and Nature

The commonest form in which Iron is found in water supplies is as ferrous bi-carbonate which is a soluble, colorless salt and exists only in solution. Its solubility is increased by increasing the free Carbon-di-oxide content of the water.

The unaerated water is clear and colorless. It develops a slight whitish haze, which on longer standing turns yellowish and then forms yellowish brown to reddish brown deposits of hydrated Ferric oxide after aeration.

Removal of Iron

Precipitation

The rate of oxidation of ferrous iron by aeration is slow under conditions of low pH and is fast under high pH conditions. Rate of precipitation and filtration are accelerated in practice by contact and catalysis. Water is allowed to trickle over coke or crushed stone. The deposition of hydrated oxides of iron and bacteria on the contact media is believed to act as catalysis which accelerates the oxidation of Iron.

Simple Technique for Iron removal

Softener

It can cause "scale" to form on the inside of pipes, water heaters, and tea kettles and so on. The calcium and magnesium precipitate out of the water and stick to things. The scale doesn't conduct heat well and it also reduces the flow through pipes. Eventually, pipes can become completely clogged.

It reacts with soap to form a sticky scum, and also reduces the soap's ability to lather. Since most of us like to wash with soap, hard water makes a bath or shower less productive.

The solution to hard water is either to filter the water by distillation or reverse osmosis to remove the calcium and magnesium, or to use a water softener. Filtration would be extremely expensive to use for all the water in a house, so a water softener is usually a less costly solution.

The idea behind a water softener is simple. The calcium and magnesium ions in the water are replaced with sodium ions. Since sodium does not precipitate out in pipes or react badly with soap, both of the problems of hard water are eliminated. To do the ion replacement, the water in the house runs through a bed of small plastic beads or through a chemical matrix called zeolite. The beads or zeolite are covered with sodium ions. As the water flows past the sodium ions, they swap places with the calcium and magnesium ions.

Eventually, the beads or zeolite contain nothing but calcium and magnesium and no sodium, and at this point they stop softening the water. It is then time to regenerate the beads or zeolite.

Regeneration involves soaking the beads or zeolite in a stream of sodium ions. Salt is sodium chloride, so the water softener mixes up a very strong brine solution and flushes it through the zeolite or beads (this is why you load up a water softener with salt). The strong brine displaces all of the calcium and magnesium that has built up in the zeolite or beads and replaces it again with sodium. The remaining brine plus all of the calcium and magnesium is flushed out through a drain pipe. Regeneration can create a lot of salty water, by the way -- something like 25 gallons (95 liters).